12v electric pumps issues with low voltage batter power

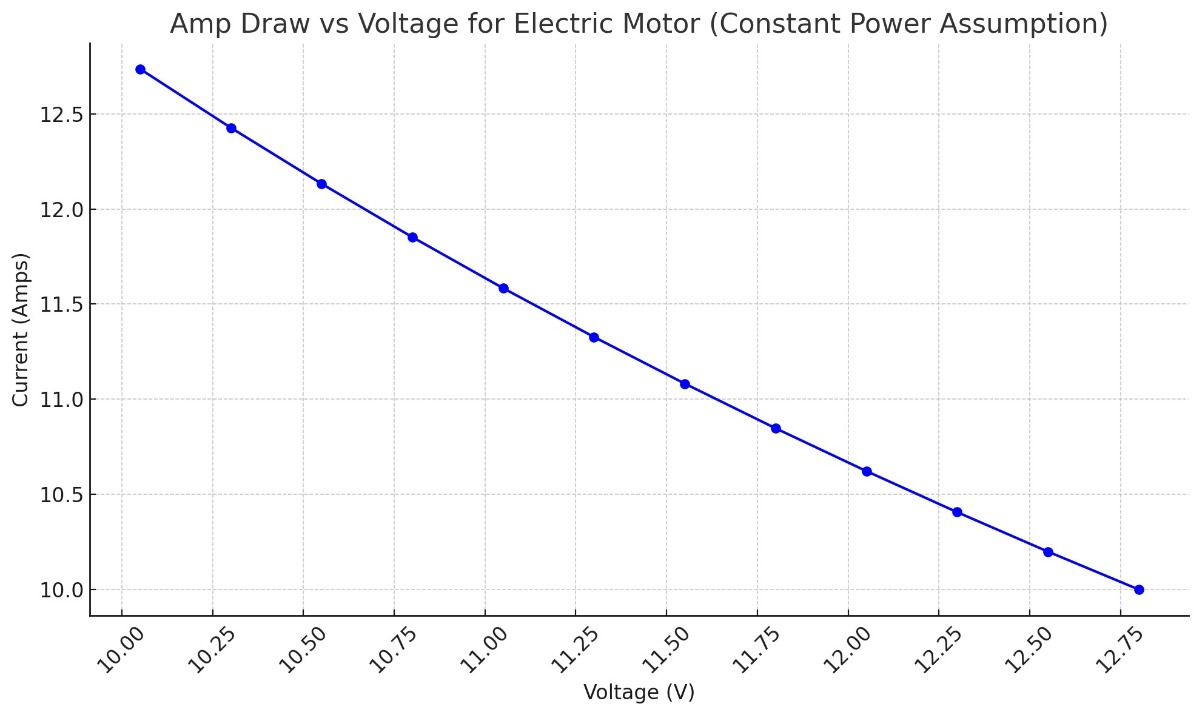

This article will help you understand the issues that impact 12v electric motors when they are run at low voltages … the excess wear plus as the voltage drops the amp draw increase bringing the battery down faster… it happens quick

Heat Generation in Motor Windings

Resistive heating (I²R losses) increases exponentially with current.

Let’s assume:

• Motor winding resistance (R) ˜ 0.2 ohms (typical small motor)

Voltage (V) | Current (A) | Power (W) | Heat (I²R) Loss (W) |

12.8 | 10.0 | 128 | 20.0 |

12.0 | 10.7 | 128 | 22.9 |

11.0 | 11.6 | 128 | 26.9 |

10.0 | 12.8 | 128 | 32.8 |

As voltage decreases, the amp draw rises to maintain the same power output. Let me know if you want to factor in real-world motor efficiency or resistance changes

Impact on Motor Life

Thermal Stress

• Insulation in windings breaks down faster at high temps.

• Rule of thumb: Every 10°C rise cuts motor life in half.

• From above, even a small voltage drop can lead to major heating, thus shortening motor life significantly.

Battery and Wiring Impact

• Wires see more amps = more voltage drop + more heat.

• Undersized wiring could overheat or damage insulation.

• Battery under high current draw sags faster, creating a feedback loop of dropping voltage & increasing amps.

Recommendations:

Action | Benefit |

Keep voltage = 12.0V under load | Avoid excessive amp draw & heat |

Use heavier gauge wiring | Minimize voltage drop |

Use thermal protection or fuses | Prevent damage from overheating |

Choose a motor rated for 20–30% margin | Better tolerance to low voltage |